MATERIAL EXPERTISE

NANOFIBERS

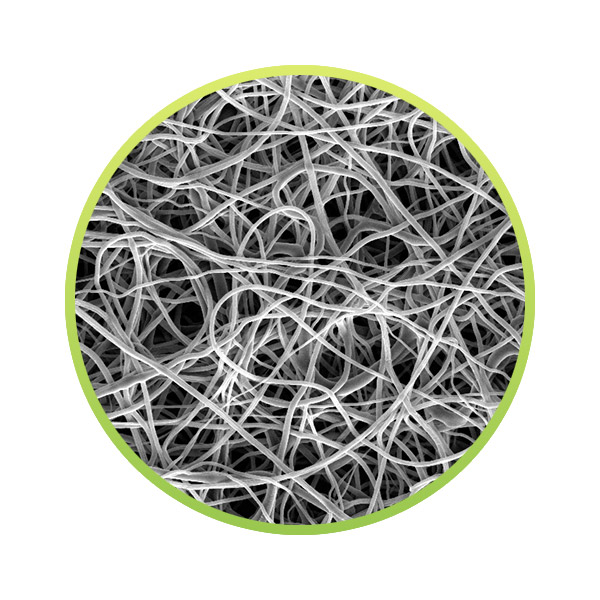

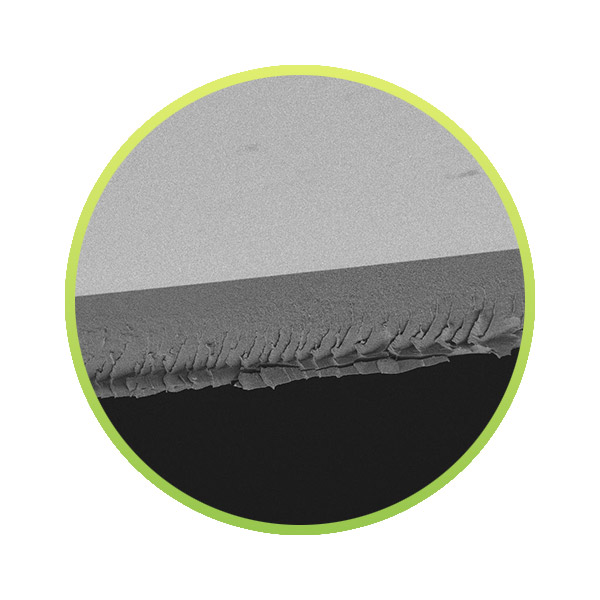

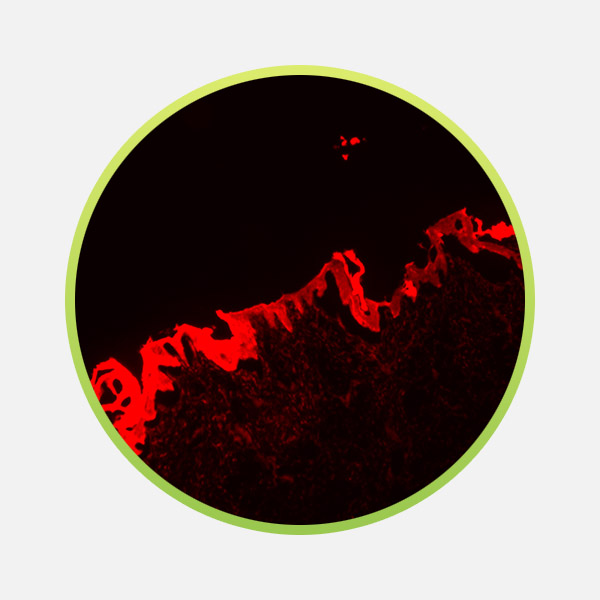

Nanofibers made from hyaluronan, its derivatives or composite fibers can be produced by electrospinning using our patented 4SPIN technology. Fibers can be highly aligned, random layers, or spun into tubes using a variety of collectors and emitters.

Using the 4SPIN allows the formation of nanofibers into different structures, stacked layers, tubes and large sheets made up of different surface area weights or perfectly oriented nanofibers.

Applications of nanofiber materials could be e.g. wounds dressings, drug delivery carriers, nano-masks, tubes for internal use in surgery or scaffolds for tissue engineering.

Furthermore, nanofibers can be combined with other forms of materials like our very own microfibers or staple fibers.

Chemical properties

Molecular weight: 15 - 150 kDa

Degree of substitution: 5 - 60%

Physical properties

Fiber diameter: 50 - 1200 nm

Surface weight: 5 - 200 g/m2

Potential Applications of Nanofibers

All nanofibers are unique for their large surface area-to-volume ratio, high porosity, mechanical strength, and flexibility compared to microfibers. Using 4SPIN technology the resulting electrospun hyaluronan nanofibers have a wide variety of potential applications.

This is by no means an exhaustive list, but potential applications could include the following:

- Wound dressings

- Scaffolds for tissue engineering

- Drug release delivery systems

- Serums for cosmetics

- Nano masks

- Coatings for medical devices e.g. stents

- Cell growth scaffolds

MICROFIBERS

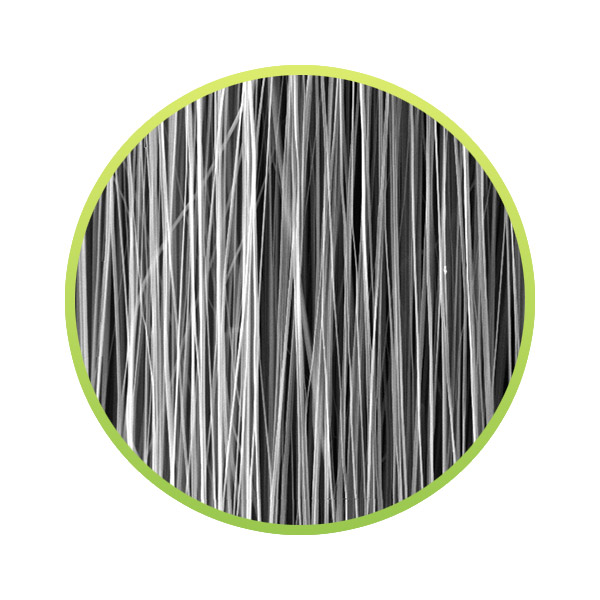

Hyaluronan based fibers can be formed into endless continual monofilaments, which can be prepared from various biodegradable derivatives of hyaluronan. They can have differing rates of water solubility, resorption time in the body and other biological and physical properties.

The mechanical properties of the fibers allow manufacturing using textile technology. Warp or weft knitting, various loop sizes, or single jersey style patterns are possible. Whether it’s a sheet or tube that is required, we can tailor make them based on your individual requirements. The characteristics of a thread can be altered by the combination of different monofilaments.

Knitted fabrics can be produced into various constructions, weights and sizes. Braided tubes or threads can be made 8 to 48 different monofilaments. Braids can be with or without a core. The fibers or textiles can be further modified by the introduction of active agents.

Chemical properties

Molecular weight: 100 - 700 kDa

Degree of substitution: 0 - 60%

Physical properties

Fiber diameter: 50 - 150 µm

Mechanical strength: 0,06 - 0,08 N/tex

Potential Applications of Microfibers

Microfibers can be prepared from native Hyaluronic Acid or from its derivatives. Solubility is adjustable and the microfibers can be woven by different textile technologies. The material can also be sterilised. Our research has shown that there is a wide variety of potential applications available for you to utilise our microfiber technology.

This is by no means an exhaustive list, but potential applications could include the following:

- Tissue regeneration

- Pre or Post-surgical use

- Drug carrier or other active ingredient delivery

- Controlled release delivery systems – non-cytotoxicity disintegration

- Controlled internal dissolution

- Tubular wraps for wound healing and implants

- Coating of implants or other medical devices

- Supplement for medical grade bandages

- Braids, yarns or knitted fabrics with various patterns

STAPLE FIBERS

Staple fibers are nonwoven textiles made from fibers that are shorter in length, typically 3 to 5mm. They can be prepared from native hyaluronan, its derivatives or a mixture of hyaluronan and other biopolymers.

These non-woven textiles can be made as self-supporting layers or can be applied to different variants of porous substrates.

The creation of multilayers and loading of active ingredients are possible. The solubility of the staple fibers in buffered saline can vary from seconds to several weeks.

Staple fibers can be sterilised and used for permanent implantable medical devices. A layer may contain only HA, with no admixture required. Multi-layered structures are also possible.

Chemical properties

Molecular weight: 350 kDa – 2.7 MDa

Materials for staple fibers deposition: PAD, PES or PU for a single step process

Physical properties

Fiber diameter: 100 - 200 µm

Self-supporting layer weight: 15 – 60 g/m2

Supported layer weight: 10 – 60 g/m2

Potential Applications of Staple Fibers

Staple Fibers are modified by a number of active substances for a variety of uses. Staple fibers can be loaded with growth factors or MRI contrast agents. The nonwoven textiles can be loaded with an active substance and potentially used internally as a local drug delivery system. Staple fibers can also be sterilised. They can also be combined with other hyaluronan forms and used in other applications e.g. with microfibers to form a multilayer application. Our research has shown that there is a variety of potential applications available for you to utilise our Staple Fiber technology.

This is by no means an exhaustive list, but potential applications could include the following:

- Drug delivery and drug release materials

- Active layers for wound healing devices

- Staple fibers can be manipulated into a 3D structure

- Antiseptics

- Haemostatic Pads

- Scaffolds loaded with growth factors

- MRI contrast agents

- Self-supporting or applied to a substrate for topical use

HYDROGELS

Hydrogels can serve as scaffolds, material for augmentation of soft tissue or for viscosupplementation.

It is possible to incorporate cells, fibres, micro or nanoparticles, or active chemical/biological substances into their structure.

Hyaluronan hydrogels and their degradation products are fully biocompatible and biodegradable.

Chemical properties

Molecular weight: 60 - 1000 kDa

Degree of substitution: 1 - 5%

Hyaluronan concentration: 0,5 - 10%

Physical properties

Stiffness (Young´s modulus): 0,5 - 20 kPa

Toughness: up to 40 000 J/m3

Viscoelastic properties (elastic modulus G´): 10 Pa - 5000 Pa

Potential Application of Hydrogels

Hydrogels can be formed by many different crosslinking techniques which have been published in many different scientific publications. Hydrogels with different mechanical properties can be formed. Our research has shown that there is a wide variety of potential applications available for hydrogels.

This is by no means an exhaustive list, but potential applications could include the following:

- Scaffolds

- Regenerative medicine

- Viscosupplementation

- Post-surgical adhesion

- Reservoir drug release

- Wound healing

- Drug delivery

- Tissue engineering

THIN FILMS

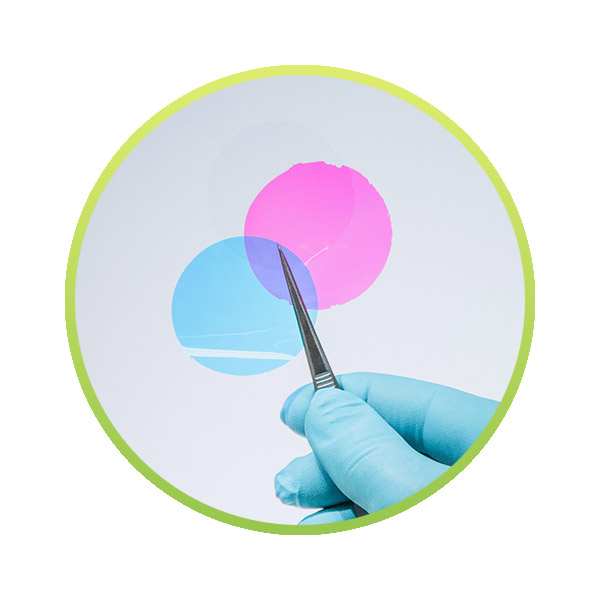

Free-standing Thin Films are prepared from native hyaluronan or from its various derivatives.

Thin Films insoluble in water can be made from hydrophobized hyaluronan or from crosslinkable hyaluronan derivatives. Crosslinking can be initiated by chemical, enzymatic reaction or by UV. This also allows us to perform the crosslinking in the presence of cells. Film swelling, degradation rates and mechanical properties can be controlled by the type of modification and the degree of substitution desired.

Contipro can prepare films with different additives such as active substances, dyes, magnetic or fluorescent nano-particles, and different types of carriers (e.g. polymeric micelles). Customised films are possible based on the individual requirements of the client.

Chemical properties

Molecular weight: 15—1000kDa

Degree of substitution: up to 60%

Physical properties

Thickness: 5 – 60 µm

Dry matter: > 85 %

Surface weight: 10 – 100 g/m2

Swelling (PBS, 37°C, hydrated state): 400 – 1500 %

Young’s modulus: up to 2 GPa

Young’s modulus (hydrated state): up to 5 GPa

Potential Applications of Thin Films

Thin Films are prepared from native HA or from its derivatives. Films insoluble in water can be made from hydrophobized (acylated) hyaluronan or from covalently cross-linkable hyaluronan derivatives. The degree of substation and modification can effect film swelling, degradation rate and the mechanical properties of the films. Our research has shown that there is a wide variety of potential applications available for Thin Films.

This is by no means an exhaustive list, but potential applications could include the following:

- Prevention of post-operative adhesions

- Tissue Engineering (Cell Sheets)

- Controlled release for active substances or growth factors

- Soluble or insoluble options

- Controlled dissolution materials

- Thin films are transparent or can be coloured

POLYMERIC MICELLES

Hydrophobized hyaluronan self-assemble in aqueous solutions into polymeric micelles with distinctive core-shell structures, which then enables non-covalent encapsulation of poorly water soluble drugs. Drug delivery using this technique is therefore an option.

Mainly because of its biodegradability, biocompatibility and safety, hyaluronan offers a number of advantages over synthetic polymers in both nonparenteral and parenteral administration routes. Furthermore, hyaluronan in the shell of polymeric micelle can be used as targeting molecule to cells or tissues overexpressing hyaluronan-binding receptors, including pathological tissues rich in CD44 receptors.

Polymeric micelles were also found to be very useful in dermatological treatments for their ability to overcome stratum corneum barrier and deliver the hydrophobic drug into deeper skin layers.

Chemical properties

Molecular weight: 10 - 20 kDa

Degree of substitution: 5 - 70%

Length of acyl chain: C6 - C18

Characteristics in dispersed form

Micelle size: 20 - 100 nm

Micelle shape: spherical particles

Potential Applications of Polymeric Micelles

Polymeric systems are used for delivery of mainly hydrophobic drugs which are entrapped in the core of the carrier. Their stability is mostly dependent on their critical micellar concentration and surface modifications.

Micelles prepared from hydrophobized derivatives of Hyaluronan have demonstrated increased bioactivity of loaded compounds in vitro and in vivo. In addition, the loaded micelles were found to be stable in cream formulations and thus they have great potential for topical applications for cosmetic and pharmaceutical purposes.

Dermatology

- Enhancing penetration of encapsulated compounds into skin, hair and nails and other topical applications

- Topical applications and carrier system

Pharmaceuticals

- The hyaluronan shell may serve as targeting molecule for tumour cells with overexpressed CD44 receptor.

- Drug delivery systems

- Parenteral applications

HAVE AN IDEA?

You can be from any industry,

you can have any goals to achieve,

however we would like to share our

knowledge and drive innovations

together with you.